Innovative Engineering in Firefighting and Rescue Ventilation

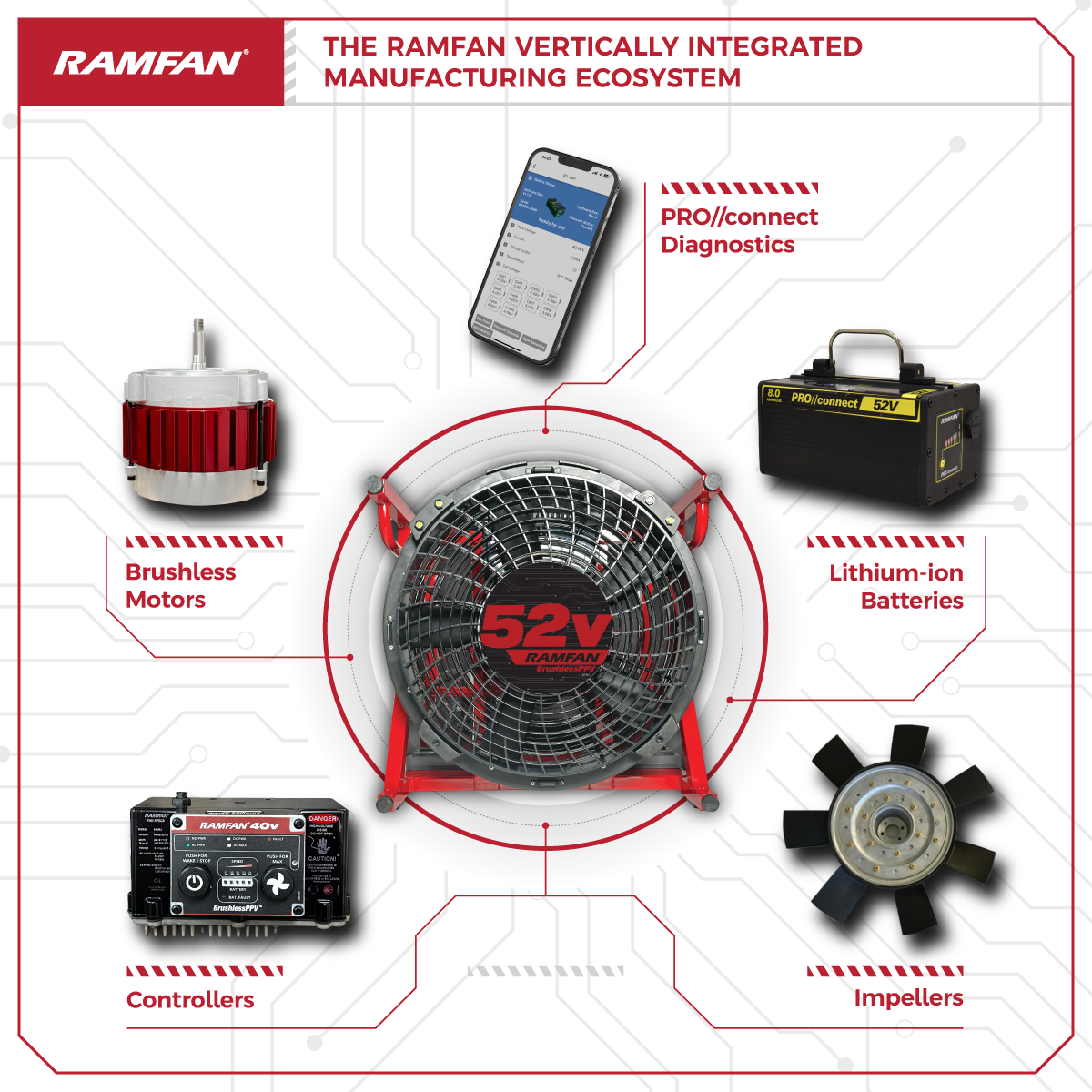

The RAMFAN Power Ecosystem

With over five decades of expertise, RAMFAN has established itself as a pioneering force in the development of highly robust and efficient BrushlessPPV fans, tailored for first responders. Our enduring commitment to innovation is rooted in extensive field experience and valuable insights garnered from global firefighting and rescue teams. This rich history of engagement and continuous improvement has culminated in the creation of the RAMFAN Power Ecosystem.

Our engineering team, recognizing the imperative for products that perform reliably in demanding conditions, has focused on achieving an optimal balance between maximal power output and uncompromising safety standards during critical operations. This objective has guided the development of our range of BrushlessPPV fans.

Optimized at every step of the process

The cornerstone of our approach has been the ground-up construction of these fans. Unlike conventional methods that rely on standard components, we have taken a comprehensive approach to design and engineering. Every major component is meticulously crafted in our facilities, ensuring that each element contributes effectively to the overall performance of the tool. This strategy enables us to optimize each component, thereby achieving unparalleled ventilation power in the fire and rescue sector.

Purpose-built for maximum preparedness

Central to the RAMFAN POWER Ecosystem are several key purpose-built components, each designed to meet the specific needs of first responders:

- Advanced Brushless Motor Technology

- Advanced Safety PRO//connect Lithium-ion Batteries

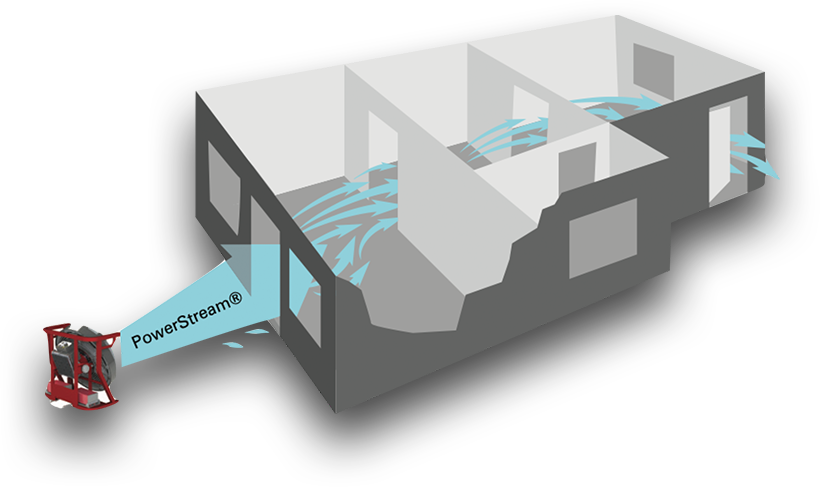

- POWERSTREAM Impeller for Optimal Focused Airflow

- Sophisticated Battery Management System (BMS)

- The PRO//connect System for Enhanced Performance Diagnostics

Dedicated to the mission

This ecosystem represents our dedication to providing first responders with the most reliable and effective ventilation tools, engineered for extreme conditions, and designed to save lives.

Advantages:

- Increased Efficiency: Brushless motors offer higher efficiency compared to traditional brushed motors due to reduced friction, leading to better performance and longer operational life.

- Enhanced Durability: The absence of brushes minimizes wear and tear, significantly extending the lifespan of the motor.

- Low Maintenance: Without brushes, there’s less maintenance required, reducing downtime and maintenance costs.

- Improved Thermal Management: Brushless motors are better at dispersing heat, which allows for more consistent performance even under demanding conditions.

- Quieter Operation: They operate more quietly, which is beneficial in noise-sensitive environments.

Advantages:

- Longer Run Time: High-capacity lithium-ion batteries offer extended operational times, reducing the need for frequent recharging.

- Lightweight and Compact: They are lighter and more compact compared to other battery types, making the equipment easier to handle and transport.

- Fast Charging: These batteries can be recharged quickly, ensuring minimal downtime.

- High Energy Density: They provide a greater energy output relative to their size, enhancing the overall power-to-weight ratio of the equipment.

- Low Self-Discharge Rate: Lithium-ion batteries have a low self-discharge rate, ensuring they retain charge for longer periods when not in use.

Advantages:

- Maximized Airflow Efficiency: The POWERSTREAM impeller is designed to maximize airflow, enhancing ventilation performance.

- Reduced Energy Consumption: Its efficient design ensures optimal performance while consuming less energy.

- Improved Performance in Varied Conditions: The impeller is engineered to perform reliably in diverse environmental conditions.

- Durability: It’s built to withstand the rigors of heavy usage, contributing to the overall durability of the fan.

- Optimized Design: The impeller’s design is optimized to work seamlessly with the other components, enhancing the system’s overall effectiveness.

Advantages:

- Battery Protection: The BMS ensures the safety of the batteries by preventing overcharging and deep discharging, thereby extending their lifespan.

- Enhanced Performance: It optimizes battery usage, ensuring consistent performance and efficiency.

- Real-Time Monitoring: The system allows for real-time monitoring of battery health and performance, facilitating proactive maintenance.

- Energy Efficiency: It ensures optimal energy distribution, improving the overall efficiency of the equipment.

- Increased Reliability: By managing the battery effectively, the BMS increases the reliability and safety of the equipment.

Advantages:

- Advanced Diagnostics: This system provides detailed performance diagnostics, allowing for better understanding and optimization of equipment performance.

- Predictive Maintenance: It enables predictive maintenance by identifying potential issues before they become significant problems.

- User-Friendly Interface: The PRO//connect system is designed to be user-friendly, making it easier to interpret data and make informed decisions.

- Real-Time Data Access: It offers real-time access to performance data, which is crucial for immediate decision-making in critical situations.

- Customizable Alerts and Reports: Users can customize alerts and reports to monitor specific aspects of equipment performance, enhancing the overall management of the equipment.

Innovative Engineering in Firefighting and Rescue Ventilation

The RAMFAN Power Ecosystem

With over five decades of expertise, RAMFAN has established itself as a pioneering force in the development of highly robust and efficient BrushlessPPV fans, tailored for first responders. Our enduring commitment to innovation is rooted in extensive field experience and valuable insights garnered from global firefighting and rescue teams. This rich history of engagement and continuous improvement has culminated in the creation of the RAMFAN Power Ecosystem.

Our engineering team, recognizing the imperative for products that perform reliably in demanding conditions, has focused on achieving an optimal balance between maximal power output and uncompromising safety standards during critical operations. This objective has guided the development of our range of BrushlessPPV fans.

Optimized at every step of the process

The cornerstone of our approach has been the ground-up construction of these fans. Unlike conventional methods that rely on standard components, we have taken a comprehensive approach to design and engineering. Every major component is meticulously crafted in our facilities, ensuring that each element contributes effectively to the overall performance of the tool. This strategy enables us to optimize each component, thereby achieving unparalleled ventilation power in the fire and rescue sector.

Purpose-built for maximum preparedness

Central to the RAMFAN POWER Ecosystem are several key purpose-built components, each designed to meet the specific needs of first responders:

- Advanced Brushless Motor Technology

- Advanced Safety PRO//connect Lithium-ion Batteries

- POWERSTREAM Impeller for Optimal Focused Airflow

- Sophisticated Battery Management System (BMS)

- The PRO//connect System for Enhanced Performance Diagnostics

Dedicated to the mission

This ecosystem represents our dedication to providing first responders with the most reliable and effective ventilation tools, engineered for extreme conditions, and designed to save lives.

Advantages:

- Increased Efficiency: Brushless motors offer higher efficiency compared to traditional brushed motors due to reduced friction, leading to better performance and longer operational life.

- Enhanced Durability: The absence of brushes minimizes wear and tear, significantly extending the lifespan of the motor.

- Low Maintenance: Without brushes, there’s less maintenance required, reducing downtime and maintenance costs.

- Improved Thermal Management: Brushless motors are better at dispersing heat, which allows for more consistent performance even under demanding conditions.

- Quieter Operation: They operate more quietly, which is beneficial in noise-sensitive environments.

Advantages:

- Longer Run Time: High-capacity lithium-ion batteries offer extended operational times, reducing the need for frequent recharging.

- Lightweight and Compact: They are lighter and more compact compared to other battery types, making the equipment easier to handle and transport.

- Fast Charging: These batteries can be recharged quickly, ensuring minimal downtime.

- High Energy Density: They provide a greater energy output relative to their size, enhancing the overall power-to-weight ratio of the equipment.

- Low Self-Discharge Rate: Lithium-ion batteries have a low self-discharge rate, ensuring they retain charge for longer periods when not in use.

Advantages:

- Maximized Airflow Efficiency: The POWERSTREAM impeller is designed to maximize airflow, enhancing ventilation performance.

- Reduced Energy Consumption: Its efficient design ensures optimal performance while consuming less energy.

- Improved Performance in Varied Conditions: The impeller is engineered to perform reliably in diverse environmental conditions.

- Durability: It’s built to withstand the rigors of heavy usage, contributing to the overall durability of the fan.

- Optimized Design: The impeller’s design is optimized to work seamlessly with the other components, enhancing the system’s overall effectiveness.

Advantages:

- Battery Protection: The BMS ensures the safety of the batteries by preventing overcharging and deep discharging, thereby extending their lifespan.

- Enhanced Performance: It optimizes battery usage, ensuring consistent performance and efficiency.

- Real-Time Monitoring: The system allows for real-time monitoring of battery health and performance, facilitating proactive maintenance.

- Energy Efficiency: It ensures optimal energy distribution, improving the overall efficiency of the equipment.

- Increased Reliability: By managing the battery effectively, the BMS increases the reliability and safety of the equipment.

Advantages:

- Advanced Diagnostics: This system provides detailed performance diagnostics, allowing for better understanding and optimization of equipment performance.

- Predictive Maintenance: It enables predictive maintenance by identifying potential issues before they become significant problems.

- User-Friendly Interface: The PRO//connect system is designed to be user-friendly, making it easier to interpret data and make informed decisions.

- Real-Time Data Access: It offers real-time access to performance data, which is crucial for immediate decision-making in critical situations.

- Customizable Alerts and Reports: Users can customize alerts and reports to monitor specific aspects of equipment performance, enhancing the overall management of the equipment.

Battery Safety

Key Features

- UL 94 V-0 Flameproof plastics

- Extruded aluminum housing 360 ̊ heat sink

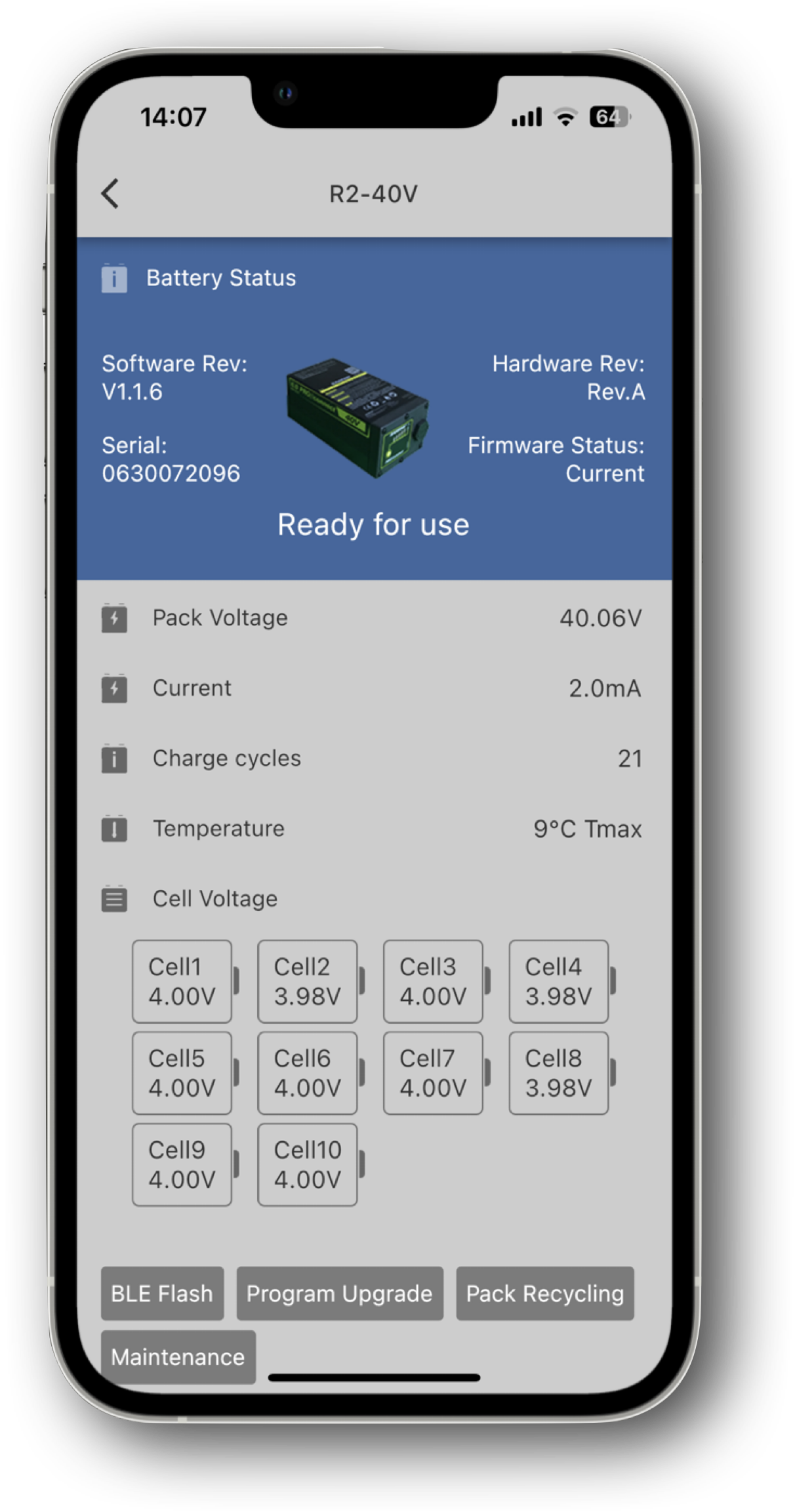

- Cell level diagnostics

- PRO//connect compatibility

- Depressurization Valve

- UL 94 V-0 Flameproof Plastics

- Complies with UL 94 standard by Underwriters Laboratories.

- Highest fire resistance rating (V-0): Stops burning within 10 seconds after flame removal.

- Produces no flaming drips, enhancing safety.

- Extruded Aluminum Housing with 360° Heat Sink

- Made through the extrusion process, shaping aluminum by pushing or drawing through a die.

- Housing doubles as a heat sink, dissipating heat in all directions.

- Cell Level Diagnostics with PRO//connect Compatibility

- Enables monitoring and analysis of individual battery cells.PRO//connect Bluetooth technology.

- Facilitates detailed management of battery health and performance.

- Depressurization Valve

- Releases excess pressure to prevent overpressure scenarios.

- Helps in avoiding system damage, explosions, or structural failure.

R-series model (40V): 216Wh energy capacity at only 4.5lbs, ideal for powering portable equipment where reliability and weight are critical factors of success. See datasheet.

M-series model (52V): Leverage bigger power gains and the highest performing technology on the market, with 375Wh energy capacity and 21,700 cells for very high capacity and ultra high-discharge. See datasheet.

- Understanding Battery Safety in Tool Development: When designing battery-powered tools, prioritizing battery safety is crucial. Firefighting PPV fans like the RAMFAN EX150Li 1.9 hp model or the smaller 0.9 hp EX50Li draw high currents (in amps) to maintain power, especially during their 30-45 minute runtime. To ensure safety, certain design measures are essential.

- Recognizing Heat Generation in Batteries: It’s a well-known fact in the battery industry that high discharge currents produce heat. However, for tools with short runtimes, like rescue tools (less than 30 seconds) or power tools (less than 5 seconds), heat buildup is minimal, and thus, special design considerations for heat management may not be necessary.

- The Risks of Overheating in Lithium-Ion Batteries: Lithium-ion batteries, commonly used in various applications, are sensitive to high temperatures. Overheating can lead to ignition, which is difficult to extinguish due to the battery’s internal fuel source. Therefore, it’s crucial to use batteries within their designated heat range.

- Understanding RAMFAN Battery Packs’ Heat Management Features:

- Cell Specification: RAMFAN’s R2 and M1 series battery packs, for PPV ventilation fans, use cells designed for a maximum continuous discharge current of 35A, ensuring a high safety margin. The Samsung 21700-40T cell is known for its high capacity and ultra-high discharge capabilities.

- Thermistor Integration: Each pack includes multiple digital temperature sensors to monitor cell temperatures in real time during operation.

- Proprietary Battery Management System (BMS): Tailored specifically for each fan model, the BMS processes data from various sensors, including cell temperature, current, and voltage. This continuous monitoring ensures the battery remains within a safe operational zone.

- Heat Dissipation Design: The hard-anodized aluminum housing serves as a 360-degree heatsink, effectively dissipating heat to maintain ambient temperature levels.

- Choosing the Right Battery Pack: When selecting a battery pack, consider the specific demands of your equipment. Packs designed for other applications may not meet the unique requirements of tools like PPV fans. Always prioritize safety and suitability in your choice.

MAINTENANCE PROCEDURE

|

BATTERY PACK

|

AFTER EACH USE

|

MONTHLY

|

EVERY YEAR

|

|---|---|---|---|

|

Gaskets

|

Inspect

|

Inspect

|

Inspect

|

|

External Connections

|

Inspect

|

|

|

|

PRO//connect Diagnostics

|

|

|

Inspect

|

|

Dischage & Recharge

|

|

Inspect

|

|

PRO//connect

Battery Management System App

INTELLIGENT FUNCTIONS

- Maintenance Mode

- Recycle Mode

AVAILABLE DATA

- Charge Cycles

- State of Health

- State of Charge

- Temperature Sensors

- Cell Voltage

- Date of Last Charge

- Fault Code Reader

PRO//connect is a wireless connectivity technology exclusive to RAMFAN. Firefighters can leverage this technology to track the condition of their battery packs over time, measure internal conditions, track cycle counts, upgrade BMS firmware, troubleshoot and even conduct basic maintenance of their battery packs.

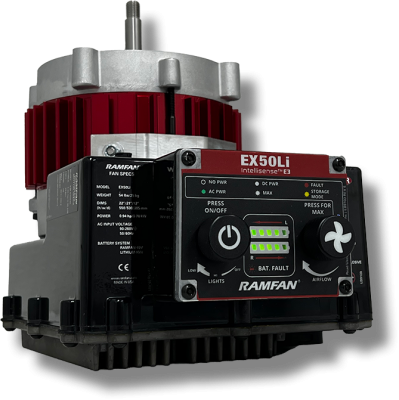

BrushlessPPV™

Motor

- Continuous Duty

- Greater than 90% efficiency

- TAEO Design

- Ultra lightweight

- Optimized for firefighting PPV use

RAMFAN has developed a range of high-performance brushless motor fans from 700W to 2.4kW, which we call our “BrushlessPPV” technology. We’ve leveraged our expertise in advanced power electronics to design a “power ladder” of choice for firefighters working with PPV equipment, based on the concept that higher voltage motors enable higher power output in a compact and lightweight package. Our singular mission is to develop the technologies necessary to replace high-performance petrol-driven fans with zero-emission alternatives.

Why does RAMFAN build its own brushless motors for first responders- what are the advantages?

Brushless electric motors are typically more efficient and lighter than conventional (brushed) motors due to several reasons:

- Improved Energy Efficiency: Brushless motors have less energy loss due to the lack of brush friction and improved heat dissipation, resulting in higher energy efficiency and longer battery life.

- Lightweight Construction: Brushless motors use permanent magnets instead of heavy copper windings in the rotor, making them lighter in weight.

- Better Control: Brushless motors can be precisely controlled using electronic speed controllers, leading to more efficient power usage and improved performance.

- Lower Maintenance: Brushless motors have fewer moving parts and do not require brush replacement, reducing maintenance costs and downtime.

- Higher Reliability: Brushless motors are less prone to wear and tear, leading to higher reliability and longer life.

Here’s another reason why RAMFAN is the most trusted brand by first responders for performance and safety. No other PPV fan company understands the rugged performance requirements of our emergency teams and builds the critical components, like brushless motors.

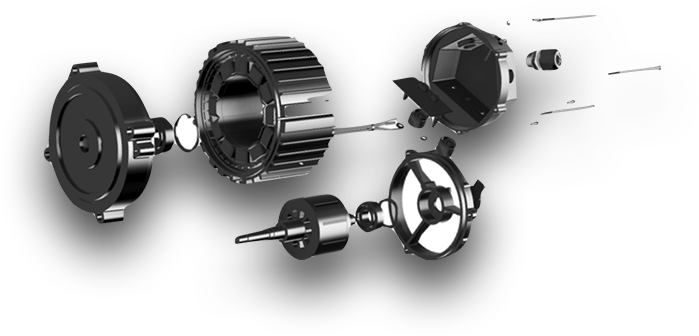

Electric brushless motors are made using several key components and manufacturing processes.

Here’s how our BrushlessPPV motors are assembled by RAMFAN engineers:

- Stator Core: The stator core is the stationary part of the motor and is typically made of laminated sheets of magnetic material, such as silicon steel. These sheets are stacked and bonded together to form the stator core.

- Stator Windings: Copper wire is wound around the stator teeth, which are projections on the stator core. The windings are typically arranged in a specific pattern, such as a star or delta configuration, depending on the motor design. The windings form electromagnets when an electric current flows through them.

- Rotor Assembly: The rotor is the rotating part of the motor and usually consists of permanent magnets mounted on a shaft. The magnets can be made of materials like neodymium, ferrite, or samarium cobalt. The rotor assembly is balanced and precision-machined to ensure smooth rotation.

- Hall Effect Sensors: In many brushless motors, Hall effect sensors are incorporated into the stator assembly. These sensors detect the position of the rotor magnets and provide feedback to the motor controller, enabling precise control of the motor’s speed and direction.

- Motor Housing: The stator assembly, rotor, and other components are housed within a protective enclosure made of materials like aluminum or plastic. The housing provides structural support, protects the internal components, and often includes mounting features for easy installation.

- Motor Controller: Brushless motors require a motor controller or drive electronics to control the flow of electric current to the stator windings. The controller receives input signals from various sources, such as Hall effect sensors or an external control system, and adjusts the timing and magnitude of the current supplied to the windings.

- Assembly: The various components, including the stator assembly, rotor, and motor controller, are carefully assembled according to the motor design specifications. Precision assembly techniques ensure proper alignment and efficient operation of the motor.

- Testing: Once the motor is assembled, it undergoes rigorous testing to ensure it meets the required performance specifications. Tests may include checks for electrical characteristics, mechanical integrity, temperature tolerance, and overall efficiency. Quality control measures are implemented to identify and address any manufacturing defects.

ADVANCED SAFETY FEATURES

MAX Mode

1, 2, GO!

Key Features

- Simple, intuitive operation

- Short-cut to maximum power

- Single button press

Available on all BrushlessPPV fans, MAX Mode gives the operator a shortcut to maximum power by using a single button press. Simply hold the fan speed button for one second and the fan automatically ramps up to maximum airflow.

AVAILABLE ON

40V and 52V BrushlessPPVTM Fans

Variable Input Power Management System

Key Features

- Variable Input Power Management System

- Maximize the performance based on available power source

- Auto detection of input power: battery & AC circuits

- Optimize for performance, safety & durability

Variable input power management (VIPM) maximizes performance of the fan based on the available power to the fan. Battery power is limited—powering a high-powered fan from a single battery doubles the discharge current required from that pack, increases cell temperatures, thus approaching or surpassing maximum current limits of cells. Spreading the load across two parallel packs allows fan performance to be increased.

115VAC circuits typically top out at 15A, or 1725W, while 230VAC allows more than double the power. Now one fan can automatically adjust its performance depending on the power available—simultaneously maximizing performance safety, and durability.

Rollover Protection System (ROPS)

Key Features

- Detect abrupt, unsafe fan movements

- Auto shutdown of fan to prevent injury

- Embedded sensor detection

- Safety technology built into all BrushlessPPV fans

The Rollover Protection System uses digital accelerometers embedded in the fan controller to automatically turn off the fan if it is abruptly knocked off its axis during operation. This ensures firefighters have both power and safety in a PPV fan when it is needed the most.

AVAILABLE ON EX, GX, WX Models

Key Features

- RAMFAN proprietary air straightener technology

- Allows for greater the setback, using air entrained

- Increases the total air volume going into a structure

- Advanced fan impeller design converts a wide, spinning mass of air into a straight, focused beam